Planet

How to Increase Concrete Strength: Tips and Techniques for Best Results

Concrete is one of the most widely used construction materials in the world, valued for its durability and strength. However, achieving optimal concrete strength is critical for the longevity and safety of structures. According to a report from the American Concrete Institute (ACI), enhancing concrete strength can significantly reduce the incidence of structural failures, which historically cost the global construction industry over $4 billion annually. Understanding the best practices for increasing concrete strength is thus vital for engineers and builders alike.

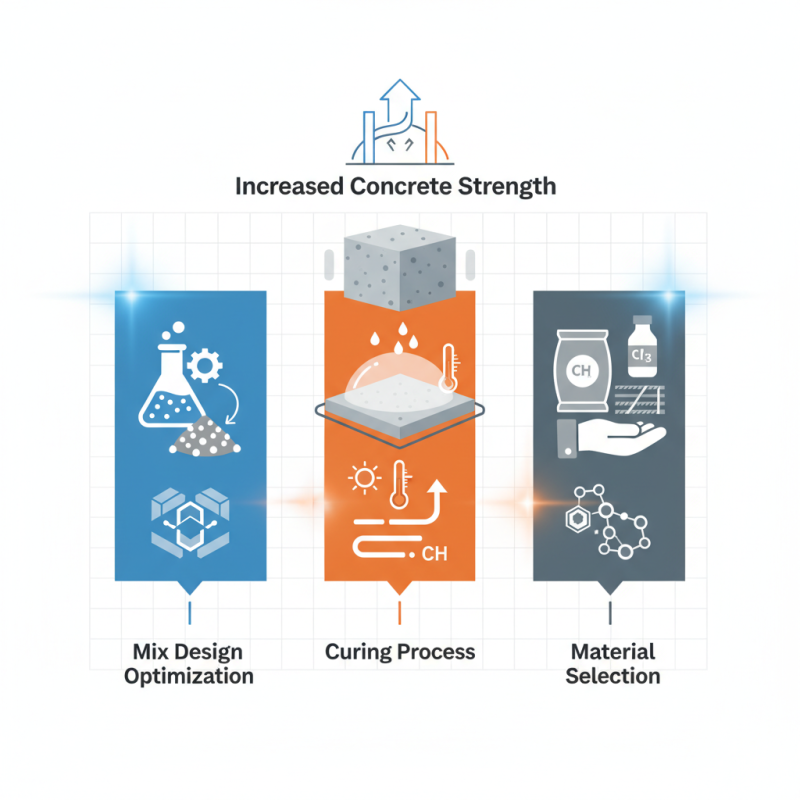

Experts in the field assert that optimizing the mix design, curing process, and material selection are key factors in achieving superior concrete strength. Dr. Emily Taylor, a renowned civil engineer and concrete specialist, emphasizes this point by stating, "The key to improving concrete strength lies in meticulous attention to detail during both the mixing and curing stages." With advancements in technology and materials science, there are numerous techniques available today that can elevate concrete strength beyond traditional methods. This article aims to explore these techniques and provide insights into best practices that will lead to the best results in concrete construction.

Understanding Concrete Strength: Key Factors and Terminology

Understanding concrete strength is essential for anyone involved in construction and civil engineering. Concrete strength primarily refers to the ability of concrete to withstand loads and stresses without cracking or failing. This strength is influenced by several key factors, including the water-cement ratio, type of aggregate used, and the curing process. The water-cement ratio is particularly crucial; a lower ratio typically results in a denser, stronger concrete. However, too little water can hinder workability, so finding the right balance is vital.

Terminology related to concrete strength can also provide valuable insights. The compressive strength, measured in pounds per square inch (psi) or megapascals (MPa), is one of the most critical parameters, indicating the material's capacity to resist axial loads. Other relevant terms include tensile strength, which measures resistance to stretching or pulling, and flexural strength, crucial for elements that experience bending. Understanding these terms helps professionals assess and enhance the performance of concrete structures effectively, guiding decisions during mixing, pouring, and curing to achieve optimal strength outcomes.

Concrete Strength Improvement Techniques

This chart illustrates the impact of various factors on concrete strength measured in megapascals (MPa). Key techniques such as adjusting the water-cement ratio, ensuring adequate curing time, selecting the right concrete mix type, monitoring temperature, and incorporating additives can significantly influence overall strength.

Selecting the Right Ingredients: Cement, Aggregates, and Water Ratio

Selecting the right ingredients is crucial in increasing concrete strength. The primary components of concrete include cement, aggregates, and water, each playing a vital role in the overall performance of the final product. The type of cement used can affect the hydration process and ultimately the durability and strength of the concrete. For instance, selecting a cement with suitable properties for the intended application can enhance the concrete’s resilience to environmental factors.

Aggregates, both fine and coarse, also significantly influence the strength of concrete. The size, shape, and grading of aggregates contribute to the overall structural integrity. Well-graded aggregates can reduce voids within the mix, leading to denser concrete that is less prone to cracking. Moreover, using high-quality aggregates that are free from impurities ensures better bonding with the cement paste, further enhancing strength.

Water is another critical ingredient, and its ratio to cement is a key factor in strength development. A lower water-to-cement ratio typically results in higher concrete strength, as it minimizes the formation of microvoids. However, sufficient water is still necessary for complete hydration of the cement. Achieving an optimal balance is essential; too little water can lead to incomplete curing, while too much can weaken the mixture. Therefore, careful consideration of ingredient selection and their proportions is essential for producing high-strength concrete.

Mixing Techniques: Achieving the Perfect Consistency for Strength

Achieving the perfect consistency in concrete mixing is crucial for increasing its strength and durability. The first step is selecting the right water-to-cement ratio. A lower ratio, around 0.4 to 0.5, usually leads to higher strength, as it minimizes the amount of water that could weaken the bond between aggregates and cement. However, it is essential to balance the amount of water to maintain workability. Utilizing water-reducing admixtures can help optimize this balance, allowing for a stronger mix without compromising on the ease of application.

In addition to the water-cement ratio, the quality and grading of aggregates play a significant role in the concrete’s overall strength. Using well-graded aggregates helps achieve a denser mix with fewer voids, enhancing strength. Properly mixing the concrete is vital; using a mechanical mixer ensures that all components are evenly dispersed, achieving the desired consistency. Mixing should continue for a sufficient time to prevent any dry patches and ensure complete hydration of the cement. Regularly testing the mix's slump can also provide immediate feedback on its workability and consistency, allowing for necessary adjustments before pouring.

Curing Methods: Enhancing Strength Through Proper Hydration

Curing is a critical phase in the concrete setting process, significantly influencing the overall strength and durability of the material. Proper hydration during curing can mean the difference between a structure that stands the test of time and one that succumbs to premature damage. According to the American Concrete Institute, insufficient curing can lead to a reduction in compressive strength by as much as 50%. This stark statistic emphasizes the importance of maintaining adequate moisture levels for at least seven days, especially for high-performance concrete mixes.

Different curing methods can be employed to enhance the hydration process effectively. Techniques such as water spraying, wet coverings, and the use of curing compounds help retain moisture during the curing period. A study published in the Journal of Materials in Civil Engineering indicated that continuous water curing improved strength by up to 20% compared to other methods, demonstrating that the choice of curing technique directly affects the mechanical properties of concrete. In addition to enhancing strength, effective curing plays a pivotal role in reducing surface cracking and increasing the longevity of concrete structures, ultimately leading to cost savings on repairs and maintenance.

How to Increase Concrete Strength: Tips and Techniques for Best Results - Curing Methods: Enhancing Strength Through Proper Hydration

| Curing Method | Description | Duration | Strength Improvement (%) |

|---|---|---|---|

| Water Curing | Keeping the surface moist by applying water regularly. | 7 days | 20-25% |

| Membrane Curing | Applying a curing compound to form a moisture-retaining film. | 7 days | 15-20% |

| Plastic Sheet Curing | Covering the concrete with wet burlap or plastic sheeting. | 7-14 days | 18-22% |

| Fogging | Creating a fine mist over the concrete surface. | Throughout the curing period | 10-15% |

| Soaking | Submerging the concrete in water for curing. | 7-14 days | 25-30% |

Testing Concrete Strength: Methods for Evaluation and Improvement

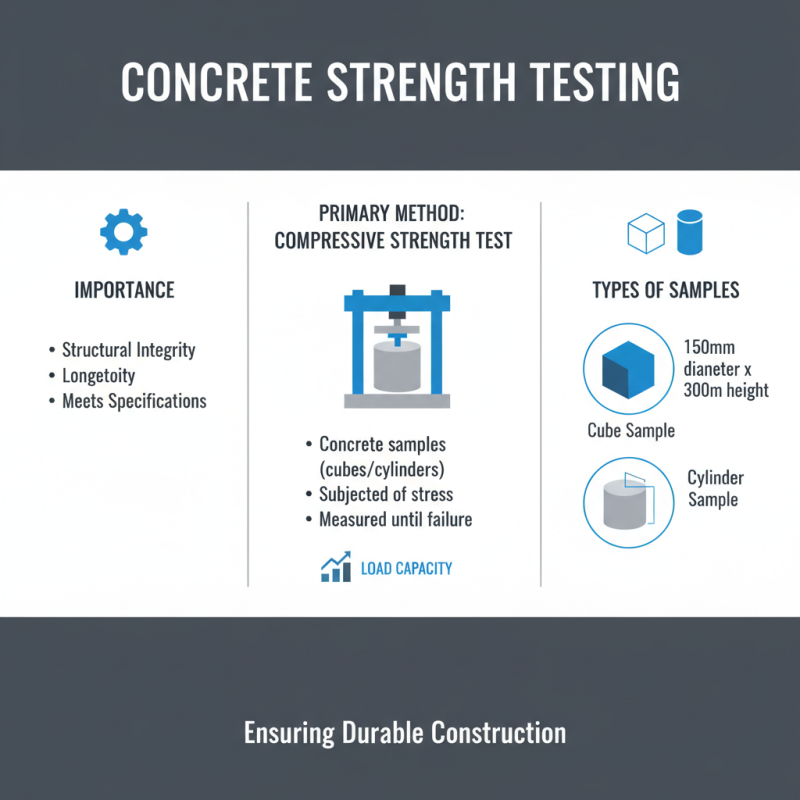

Testing concrete strength is a crucial aspect of ensuring structural integrity and longevity in construction projects. Various methods are employed to evaluate concrete strength, each with its advantages and limitations. The most commonly used technique is the compressive strength test, where concrete samples, typically in the form of cubes or cylinders, are subjected to stress until failure occurs. This method provides a clear measure of the material's ability to withstand load and is essential for determining whether the concrete mixes meet the specified requirements.

In addition to compressive strength testing, non-destructive testing methods, such as rebound hammer tests and ultrasonic pulse velocity tests, are increasingly utilized. These techniques allow for the evaluation of concrete strength without causing damage to the structure. The rebound hammer test measures the surface hardness, which correlates to compressive strength, while ultrasonic pulse velocity assesses the quality and uniformity of the concrete by measuring the speed of sound waves traveling through it. By employing a combination of these methods, engineers can gain a comprehensive understanding of concrete strength, making informed decisions about maintenance, repairs, or adjustments in mix design to enhance overall performance.

Related Posts

-

Top 10 Ready Cement Products to Transform Your Construction Projects in 2025

-

2025 How to Choose the Best Cement Maker for Your Construction Needs

-

10 Essential Tips for Using Cement at Home Like a Pro

-

How to Choose the Right Portland Concrete for Your Construction Project

-

2025 Top Trends in Mixed Concrete: Innovations Driving 10% Industry Growth

-

Exploring the Durability of Concrete Houses: Why 70% of Homeowners Prefer This Modern Build

- The Monarch Cement Company

- 449 1200 Street

Humboldt, KS

66748 - (620) 473-2222

- sale@rileydesignbuild.com