Planet

How to Choose the Best American Concrete for Your Construction Project

The construction industry in the United States consistently relies on American concrete as a fundamental material. According to the American Concrete Institute, concrete is one of the most widely used construction materials, with approximately 5.5 billion cubic yards poured each year, showcasing its vital role in infrastructure development and urbanization. Selecting the right type of American concrete for a construction project is crucial, as it directly influences the durability, sustainability, and overall performance of structures.

In recent years, industry reports indicate a growing emphasis on the environmental impact of construction materials, with concrete production accounting for roughly 8% of global carbon dioxide emissions. This has led to innovations in sustainable concrete solutions, including recycled aggregates and reduced cement ratios. As project stakeholders increasingly seek to improve sustainability, understanding the various options within the American concrete market becomes essential for making informed decisions that meet both structural requirements and environmental responsibilities. Therefore, navigating the choices available to ensure optimal performance while also considering ecological implications is paramount for any successful construction endeavor.

Understanding Different Types of Concrete Used in American Construction

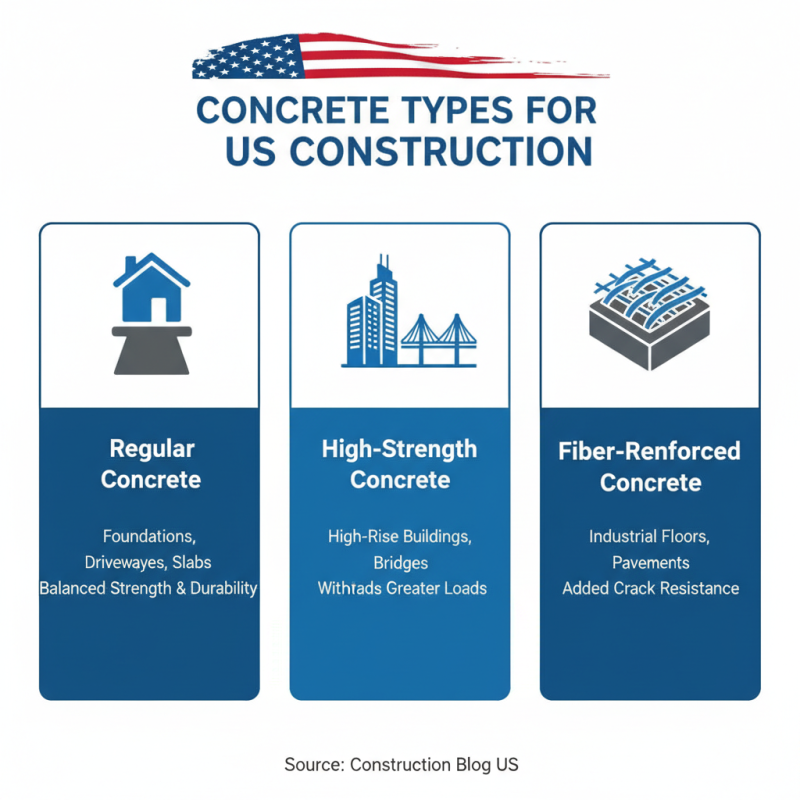

When selecting the best concrete for a construction project in the United States, it's crucial to understand the different types available and their applications. Among the most commonly used types are regular concrete, high-strength concrete, and fiber-reinforced concrete. Regular concrete is typically used for standard foundations, driveways, and slabs, offering a good balance of strength and durability for everyday applications. High-strength concrete, on the other hand, is formulated to withstand greater loads and is often used in high-rise buildings and bridges, where structural integrity is paramount.

Another significant type of concrete is fiber-reinforced concrete, which incorporates fibers to enhance its tensile strength and crack resistance. This type is ideal for pavements and slabs subjected to heavy traffic and extreme conditions. Additionally, there are specialty concretes such as self-consolidating concrete, which flows easily into complex forms, eliminating the need for vibration during pouring. Understanding these variations allows contractors and builders to select the most suitable concrete for their specific needs, ensuring longevity and stability in their construction projects.

Factors to Consider When Selecting Concrete for Your Project

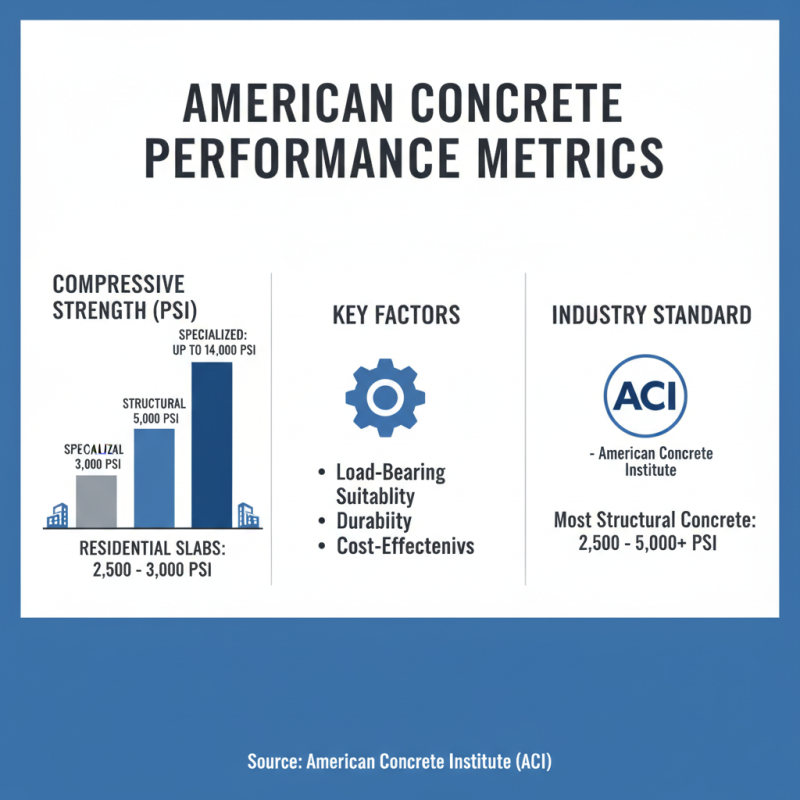

When selecting concrete for your construction project, several key factors should be taken into consideration to ensure optimal performance and longevity. One of the most crucial aspects is the concrete's compressive strength, which is a measure of how much load it can bear. According to the American Concrete Institute, the standard strength for most structural applications is typically between 4,000 to 5,000 psi (pounds per square inch). Projects that anticipate higher loads, such as bridges or high-rise buildings, may require concrete with strengths exceeding 7,000 psi.

Another significant factor is the concrete mix design, which affects not just strength but also durability and workability. The choice between normal, high-strength, or even specialized mixes, such as self-consolidating concrete (SCC), should reflect the environmental conditions the concrete will face. For instance, regions susceptible to freeze-thaw cycles necessitate air-entrained concrete to reduce the risk of cracking, with studies indicating that proper use of air-entrainment can increase the material’s lifespan by 25-50%. Additionally, the water-cement ratio plays a critical role in determining the final properties of concrete; a lower water-cement ratio usually leads to higher strength and durability, but may pose challenges in terms of workability.

Lastly, the selection of aggregates also impacts the performance and sustainability of concrete. The quality, size, and grading of aggregates can influence both the structural integrity and the environmental impact of the project. Recent data from the National Ready Mixed Concrete Association highlights that optimizing aggregate use can lead to a reduction in material costs and waste, promoting more sustainable construction practices. Therefore, careful consideration of these factors will help ensure that the concrete chosen is suitable for the specific demands of the construction project, ultimately leading to better performance and greater efficiency.

Evaluating Performance Metrics of American Concrete Options

When evaluating performance metrics of American concrete options for construction projects, several key factors must be considered to ensure the selection of the most suitable concrete type. The compressive strength, typically measured in pounds per square inch (psi), is a critical performance metric. According to the American Concrete Institute, most structural concrete typically ranges from 2,500 psi to over 5,000 psi, with specialized mixes achieving up to 14,000 psi for specific applications. Understanding these strength ratings helps in determining the concrete's suitability for load-bearing structures.

In addition to compressive strength, the durability of concrete must also be assessed. Factors such as permeability, freeze-thaw resistance, and chemical resistance are vital indicators of a concrete mix's long-term performance. The National Ready Mixed Concrete Association emphasizes that lower permeability significantly enhances durability, reducing the likelihood of failure over time. It is also essential to consider the environmental impact of concrete, with options such as recycled aggregates now available, which can improve sustainability without compromising performance.

**Tips:** When selecting concrete, always review third-party test reports and certifications to validate performance claims. Prioritize concrete mixes that meet or exceed industry standards for your specific application. Consulting with a structural engineer can provide insights tailored to your project's unique requirements, ensuring optimal performance and longevity of your concrete structures.

Sustainability and Environmental Impact of Concrete Choices

When considering concrete options for your construction project, sustainability is an increasingly important factor. The production of traditional concrete contributes to approximately 8% of global carbon dioxide emissions, primarily due to cement manufacturing. According to a report by the Global Cement and Concrete Association, switching to alternative cement sources and incorporating recycled materials can significantly reduce these emissions. For instance, using fly ash or slag in the concrete mix can decrease the carbon footprint by up to 30%, making these options not only environmentally friendly but also cost-effective.

Similarly, the environmental impact of your concrete choices extends beyond just the production phase. The lifespan and performance of concrete structures are essential to sustainability. Well-designed concrete can enhance durability and reduce necessary maintenance, thus lowering long-term resource consumption. The Portland Cement Association highlights that concrete structures, when properly designed, can last over 50 years, minimizing the need for replacements or extensive repairs. Additionally, innovations such as permeable concrete help manage stormwater runoff and mitigate flooding, demonstrating that thoughtful concrete choices can lead to a more sustainable urban environment.

Cost Analysis and Budgeting for Concrete in Construction Projects

When budgeting for concrete in your construction projects, it's essential to conduct a thorough cost analysis. Start by understanding the various factors that influence concrete prices, including the type of concrete selected, regional market conditions, and the specific requirements of your project. Materials, labor, and additional services such as delivery and mixing can all contribute to the overall cost. For more accurate budgeting, get multiple quotes and evaluate the different options available.

Tips for effective budgeting include establishing a clear project scope from the beginning to avoid unexpected costs later. Consider potential fluctuations in material prices due to market volatility and incorporate a contingency budget to handle unforeseen expenses. Additionally, using detailed measurements and accurate calculations can help prevent waste and save costs.

Another valuable tip is to seek bulk purchasing options or discuss long-term contracts with your suppliers. This approach can lead to cost savings through bulk discounts or fixed pricing, providing you with more stable budgeting forecasts. Always stay updated on industry trends and cost changes, as this knowledge can empower you to make informed decisions throughout your project.

How to Choose the Best American Concrete for Your Construction Project

| Concrete Type | Cost per Cubic Yard ($) | Strength (psi) | Typical Uses | Duration to Set (Hours) |

|---|---|---|---|---|

| Standard Ready-Mix | $130 | 3000 | Residential Foundations | 4-6 |

| High-Strength Concrete | $170 | 5000 | Commercial Buildings | 6-8 |

| Fiber-Reinforced Concrete | $150 | 4000 | Pavements, Slabs | 4-5 |

| Sustainable Green Concrete | $160 | 3500 | Eco-Friendly Projects | 5-7 |

| Decorative Concrete | $200 | 3000 | Driveways, Patios | 4-6 |

Related Posts

-

Understanding the Benefits of American Concrete in Modern Construction Techniques

-

Top 10 Ready Cement Products to Transform Your Construction Projects in 2025

-

Why You Should Choose Masonry Cement for Your Next Construction Project

-

Top 10 Benefits of Using Mixed Cement for Your Construction Projects

-

What is Cement Tech and How It Revolutionizes the Construction Industry

-

2025 Top Trends in Mixed Concrete: Innovations Driving 10% Industry Growth

- The Monarch Cement Company

- 449 1200 Street

Humboldt, KS

66748 - (620) 473-2222

- sale@rileydesignbuild.com